Understanding Pigging Applications: Key Benefits and Industry Uses

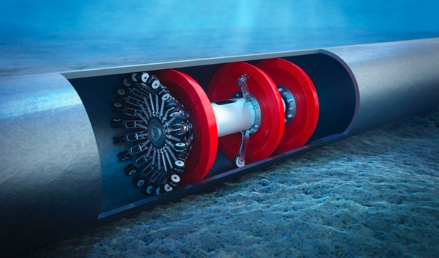

Pigging applications have become a crucial aspect of many industrial processes, particularly those involving pipelines. In simple terms, pigging involves the use of devices, often referred to as “pigs,” which are inserted into pipelines to perform various tasks, such as cleaning, inspection, and separation of different products. These applications provide an array of benefits, including improving operational efficiency, reducing product contamination, and maintaining the overall integrity of pipelines. This article explores the key advantages and uses of pigging applications across various industries, shedding light on their importance in modern pipeline management.

What Are Pigging Applications?

Pigging applications involve the use of a device called a “pig,” which is designed to travel through pipelines. These pigs are typically cylindrical and are propelled by the flow of the product inside the pipeline. The primary purpose of pigging is to clean the pipeline, but it can also be used for tasks such as separating different products, inspecting pipeline conditions, and ensuring the smooth operation of pipeline systems.

The word “pig” stands for Pipeline Inspection Gauge, but it is also used to describe any tool that is inserted into a pipeline for cleaning, inspection, or maintenance. Pigging applications are used in various industries to enhance the performance of pipeline systems and ensure that they operate at maximum efficiency.

Types of Pigging Applications

There are several types of pigging applications that cater to different needs, depending on the industry and specific pipeline requirements. Some of the most common pigging applications include:

1. Cleaning Pigging

Cleaning pigging is one of the most common applications. It involves using pigs designed to remove debris, scale, and other residues that can accumulate within pipelines over time. These residues can cause blockages, reduce flow efficiency, and damage the pipeline if left unchecked.

Cleaning pigs are equipped with brushes, scraping tools, or foam elements that help remove buildup along the pipeline walls. These pigs are essential for industries that rely on the continuous flow of products, such as oil and gas, food and beverage, and pharmaceuticals. By cleaning the pipelines, companies can ensure that their products are transported without interruption and without contamination.

2. Inspection Pigging

Inspection pigging uses pigs equipped with advanced sensors to inspect the internal condition of pipelines. These pigs can detect issues such as corrosion, cracks, or other structural problems within the pipeline. The inspection process is non-destructive, meaning it does not require any physical alterations to the pipeline.

Inspection pigs are invaluable for industries like oil and gas, where pipelines can be exposed to harsh conditions and are prone to wear and tear. Regular inspection pigging helps detect problems before they become severe, allowing for timely maintenance and avoiding costly repairs or downtime.

3. Separation Pigging

Separation pigging is used to separate different products within the same pipeline. This application is particularly important for industries that handle multiple products in the same pipeline, such as oil, gas, or food processing. Separation pigs are designed to create a barrier between different products, preventing them from mixing.

Read also: Why Translation Services Are Crucial for Global Business

For instance, in the oil industry, separation pigging is used when different grades of crude oil need to be transported through the same pipeline. The pig creates a seal between different batches, ensuring that each product remains distinct and preventing cross-contamination. This is crucial for maintaining product quality and adhering to regulatory standards.

4. Batching Pigging

Batching pigging refers to the use of pigs to manage different product batches within the same pipeline. It is especially useful in industries such as food processing and chemicals, where different products must be transported one after another but without mixing. Batching pigs are used to clear the pipeline between product batches, ensuring that each product is processed without interference from the previous batch.

By using batching pigging, manufacturers can avoid costly product recalls or contamination issues that could arise from mixing different products. This type of pigging is highly effective in maintaining product quality and reducing waste.

5. Flow Assurance Pigging

Flow assurance pigging is critical in industries where the flow of materials through pipelines needs to be monitored and maintained at optimal levels. This type of pigging ensures that the pipeline’s capacity to transport products efficiently is not compromised.

Flow assurance pigs are used to remove any buildup that could obstruct the flow of materials. This application is especially important in industries like oil and gas, where the flow of hydrocarbons must be maintained at a steady rate. Without proper flow assurance, the risk of pipeline blockages, pressure drops, and system failures increases significantly.

Advantages of Pigging Applications

The implementation of pigging applications offers several advantages to industries that rely on pipelines for transportation. Some of the key benefits include:

1. Improved Pipeline Efficiency

One of the primary benefits of pigging applications is the improvement in pipeline efficiency. By cleaning the pipeline and removing buildup, pigging ensures that products can flow freely without obstruction. This leads to a reduction in pressure drop, which means that less energy is required to transport products, thus improving the overall efficiency of the pipeline system.

2. Enhanced Product Quality

Pigging applications, especially cleaning and separation pigging, help maintain product quality by preventing contamination between different batches. In industries such as food processing and pharmaceuticals, product purity is critical, and any contamination could lead to safety concerns or regulatory violations.

By ensuring that pipelines are thoroughly cleaned between product batches, pigging helps maintain the integrity of the products being transported. This results in better product quality, fewer recalls, and compliance with industry standards.

Conclusion

Pigging applications have revolutionized the way industries maintain and manage pipeline systems. From improving pipeline efficiency and product quality to reducing costs and downtime, pigging systems offer numerous benefits across a variety of sectors. As industries continue to grow and evolve, the role of pigging applications will remain indispensable, ensuring the smooth and efficient operation of pipeline networks.